The Only Guide for Plant Conveyors And Systems

Table of ContentsExamine This Report on Plant Conveyors And Systems5 Easy Facts About Plant Conveyors And Systems ExplainedAll About Plant Conveyors And SystemsNot known Facts About Plant Conveyors And SystemsWhat Does Plant Conveyors And Systems Do?The 9-Minute Rule for Plant Conveyors And Systems

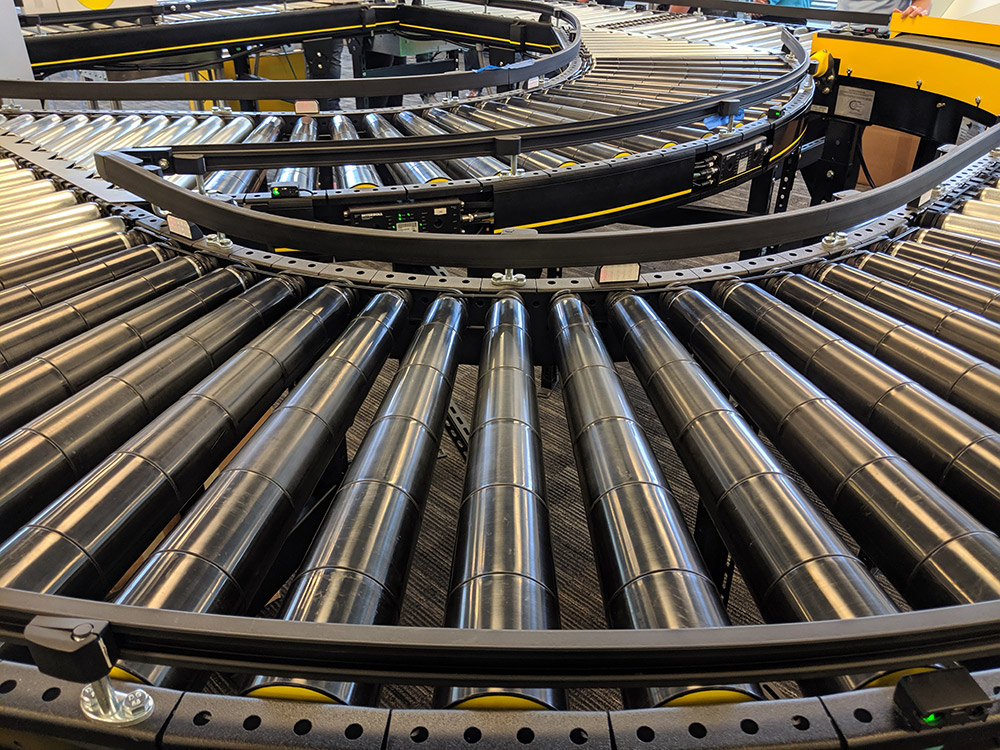

Carryback is usual in all belt systems as well as is one of the major problems that triggers belt breakdowns. Drive: The drive for the belt can be located in different positions in the communicating system. For the majority of belt conveyors, the drive is situated at the discharge or head of the belt - Plant Conveyors and Systems.AC electric motors are usually used to power the sheave that moves the belt. Phase Five Conveyor System Applications As automation and also manufacturing have actually come to be a lot more highly progressed, conveyors have quickly turned into an important part of product handling as well as motion as well as boosting the rate of different manufacturing procedures.

Conveyors transport the item into the high temperature level heating systems for the sintering process. Packaging: A packaging conveyor is created to assist with product packaging, such as positioning ended up items in containers, effective labeling, or prep work of products for shipping. The function of a packaging conveyor system is to relocate products from completion and assembly for delivery.

The Main Principles Of Plant Conveyors And Systems

Press out conveyors are used to get rid of shaped pieces from the pressing line or on various other operations. Airport: Though airports have individuals moving conveyors, the main sharing system is for baggage handling, which accelerates the procedure of getting luggage from the checkin counter to the aircraft and off the aircraft to travel luggage pickup.

Mining conveyors differ in size and also length, the majority of them are on a slope and relocate a number of lots of material. Mining Conveyor Automotive: The automobile sector utilizes numerous varieties of conveyors for material handling.

The one aspect that makes them special is the need to fulfill governmental policies for hygiene and cleanliness. Printing: Publishing conveyors, for screen printing, use a conveyor clothes dryer procedure for drying display published material. There are various other methods for drying out display prints, conveyor clothes dryers are made use of for huge volume manufacturing as well as come in several selections.

Rumored Buzz on Plant Conveyors And Systems

Chapter Six Advantages of a Conveying System Conveyors have become a fundamental part of manufacturing, mining, manufacturing, and ending up operations. They enhance effectiveness and aid minimize labor prices. Using conveyors has actually led to higher quantity, boosted manufacturing, and prevention of injuries. No matter the sector, conveyors have been proven to be an increase for production processes.

Continual Procedure: Materials are continuously filled and unloaded for lengthy durations of time without disturbance or blockage. Automated Unloading: Conveyors can be developed to instantly unload materials without the demand for manual work. Control of Motion: Conveying systems have speed controls to keep track of just how quickly things move along the system, which removes the worry for dealing with problems or breakage.

7 Easy Facts About Plant Conveyors And Systems Described

The image listed below is of a safety cable television pick up conveyors. High Quantity: Conveyors are a part of a computerized system with the ability of relocating hundreds or countless lots of material per hour or in a day. Chapter Seven Conveying System Malfunctions There are breakdowns that can take place in see it here a sharing system that is constantly being used.

Conveying System Malfunctions Mistracking Mistracking is likewise understood as belt drift, where the belt wanders to one side. Taken Rollers Part of the mistracking issue might be linked with a confiscated roller, which can lead to sharp edges that would certainly shut down the system.

Slippage Slippage on a belt conveyor can take place due to tension being expensive or low, which can bring about extending and also conveyor belt slippage. Obstruction Conveyor systems are designed to run constantly without disruption or deduction. Any form of obstruction can be damaging to the system as well as bring about significant repair services.

Plant Conveyors And Systems Things To Know Before You Get This

The internet most typical is when material sticks to the belt as well as goes past the transfer factor and also falls off. Spillage When a belt conveyor is strained, or as well jam-packed, materials can drop off the sides.

Screw Conveyors Tiredness in a screw conveyor happens when there is build up in the pipeline as the conveyor transforms. In that void, product gathers and also hardens.

Facts About Plant Conveyors And Systems Uncovered

Fixing or Change Deciding to change a component on a system has a number of expense factors, such as the downtime for the system, discovering the ideal part, and employing a specialist to do the replacement. This expense can be balanced out with normal upkeep as well as monitoring of the system. Motor The key part of a conveying system is its motor (Plant Conveyors and Systems).

Birthing failing can be credited to lubrication issues. This can be prevented by having a routine maintenance cycle for bearing maintenance. The temperature level of the electric motor should never ever surpass its advised operating temperature level. Pulley Bearings Sheave bearings are completely filled with lube to maintain out water and also pollutants. For the most part, they never require repair service if they are consistently inspected and maintained.